Museum lead

Mr John Spratt

Electron probe microanalyst

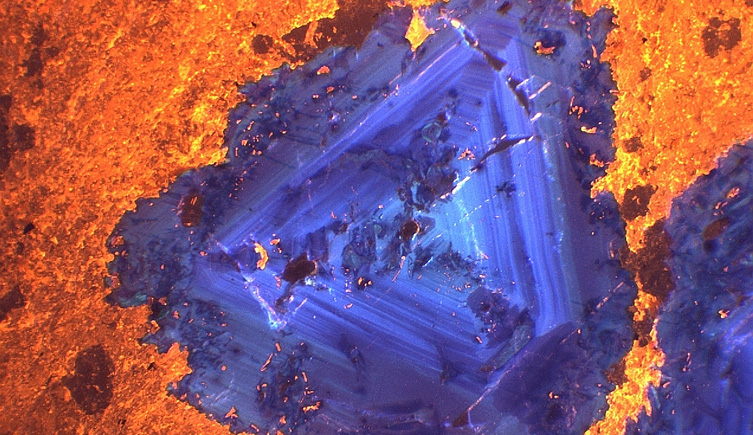

True-colour cathodoluminescence image taken with the Cameca SX100. Fluorite (blue-violet) is shown associated with calcite (yellow-orange) in a carbonatite from India.

The wavelength dispersive X-ray (WDX) electron microprobe is capable of unattended overnight elemental analysis of materials in polished sections or blocks. Images from the sample surface can also be obtained.

Analysis is achieved by focusing a beam of electrons onto the sample surface, which produces X-rays with wavelengths or energies characteristic of the elements present.

An artificially coloured backscattered electron (BSE) image and three X-ray maps showing the distribution of tin (Sn), niobium (Nb), and scandium (Sc) in a small grain of tin- and scandium-bearing titanite in a sample of rhyolite from north Wales. The grain displays sector zoning. Scale bar = 100µm.

Samples need to be polished, either as circular blocks or thin sections, and carbon coated. Samples that need to be prepared (cut, mounted and polished) should be presented to the preparation laboratory at least four weeks prior to the Cameca SX100 booking.

The Museum’s Imaging and Analysis Centre uses on-site saws, laps and polishing equipment to produce a range of thin and polished sections, blocks and wafers of palaeontological, mineralogical, biological and industrial materials such as concretes.

Prior to analysis many samples - particularly those containing minerals - need to be coated with a thin film of conducting media to dissipate the excess charge produced by the electron beam. A film of carbon around 30 nanometres thick is usually used.

Mr John Spratt

Electron probe microanalyst

Technique: electron probe microanalysis (EPMA)

Quantitative analyses obtained for: elements with an atomic number greater than five

Typical detection limits: in the order of 0.02 weight per cent